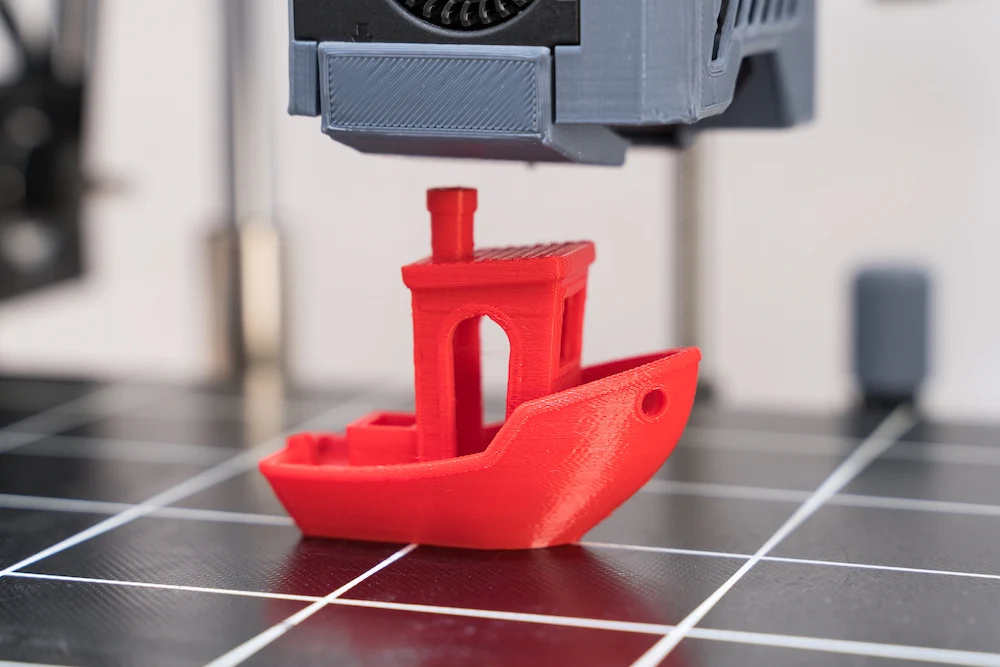

The electronics industry is one of the most dynamic and fast-paced sectors, constantly driven by innovation, miniaturization, and the need for more efficient production methods. Commercial 3D printing services are increasingly being adopted by this industry, offering new possibilities for design, rapid prototyping, and production of complex electronic components. This article explores how 3D printing is revolutionizing the electronics industry and paving the way for the next generation of electronic devices.

Rapid Prototyping and Innovation

Innovation is the lifeblood of the electronics industry, where the pressure to develop new products and features is intense. Commercial 3D printing services play a crucial role in accelerating the prototyping phase, allowing companies to quickly produce and test new designs. Traditional methods of prototyping electronic components can be time-consuming and costly, often requiring multiple iterations before a final design is achieved. With 3D printing, engineers can rapidly create prototypes, evaluate their performance, and make necessary adjustments in a fraction of the time.

This rapid prototyping capability not only speeds up the development process but also fosters greater innovation. Engineers and designers can experiment with new ideas, test unconventional geometries, and explore novel materials without the constraints imposed by traditional manufacturing methods. This freedom to innovate is essential in an industry where staying ahead of the competition requires constant advancement and improvement.

Customization and Complex Geometries

The demand for customized electronic devices is growing, driven by consumers’ desire for products that cater to their specific needs and preferences. Commercial 3D printing services enable the production of highly customized components, from bespoke enclosures to unique internal structures that optimize the performance of electronic devices. This level of customization is particularly valuable in specialized markets, such as medical electronics, where devices need to be tailored to the individual requirements of each patient.

In addition to customization, 3D printing allows for the creation of complex geometries that would be difficult or impossible to achieve with traditional manufacturing techniques. For example, 3D printing can be used to produce intricate cooling systems for electronic devices, optimizing heat dissipation and improving overall performance. Similarly, components with integrated functions, such as antennas or sensors, can be produced in a single printing process, reducing assembly time and costs.

Reducing Time to Market

In the electronics industry, reducing time to market is critical to staying competitive. Commercial 3D printing services enable companies to shorten production cycles by reducing the time required for tooling, manufacturing, and assembly. Traditional manufacturing methods often involve lengthy processes to create molds and tools, which can delay production and increase costs. With 3D printing, parts can be produced directly from digital designs, eliminating the need for tooling and allowing for faster turnaround times.

This ability to rapidly transition from design to production is particularly valuable in industries like consumer electronics, where product life cycles are short, and market demands can change rapidly. By leveraging 3D printing, companies can quickly respond to new trends, introduce innovative products, and capitalize on emerging opportunities, all while maintaining a competitive edge.

Sustainability and Material Efficiency

Sustainability is an increasingly important consideration in the electronics industry, where the production of electronic waste and the use of hazardous materials pose significant environmental challenges. Commercial 3D printing services support sustainability by enabling more efficient use of materials and reducing waste. Unlike traditional manufacturing, which often involves cutting away material to create parts, 3D printing is an additive process, meaning that material is only used where it is needed.

This approach not only reduces material waste but also allows for the use of advanced, eco-friendly materials that are difficult to process with traditional methods. Additionally, commercial 3d printing services can reduce the environmental impact of electronics production by enabling local manufacturing, thereby reducing the need for transportation and associated emissions.

Conclusion

Commercial 3D printing services are advancing the electronics industry by enabling rapid prototyping, customization, and the production of complex geometries. By reducing time to market and supporting sustainability, 3D printing is helping companies innovate and stay competitive in a fast-paced industry. As the technology continues to evolve, its impact on the electronics industry is likely to grow, offering new opportunities for efficiency, innovation, and sustainability.